VIRTUAL BUYING OFFICE (VBO)

There are no better decisions made than decisions based on data

Introducing Virtual Buying Office (VBO), our complete supply chain management platform, designed to optimise sourcing activities and enhance transparency for all partners involved in complex or large supply chains, making sure you make the best decisions for your business based on facts and hard evidence.

With planning, tracking, and reporting functions that provide visibility and connectivity from PO creation through final delivery down to SKU level, VBO allows you to manage your supplier base proactively, optimise information flow, and configure your own reporting system—enhancing control and visibility along your supply chain.

IN SHORT, WHAT IS VBO?

Virtual Buying Office (VBO) is a customizable Supply Chain Management platform that integrates seamlessly with your ERP system. It enables real-time tracking and analysis of all purchase orders down to SKU level. With features like carrier management, contract overview, and direct vendor booking, VBO streamlines supply chain monitoring and empowers proactive decision-making—saving you time and reducing costs.

Think of VBO as the 'command center for your logistics operations,' monitoring every movement and ensuring smooth operations at all times.

WHAT ARE THE FEATURES

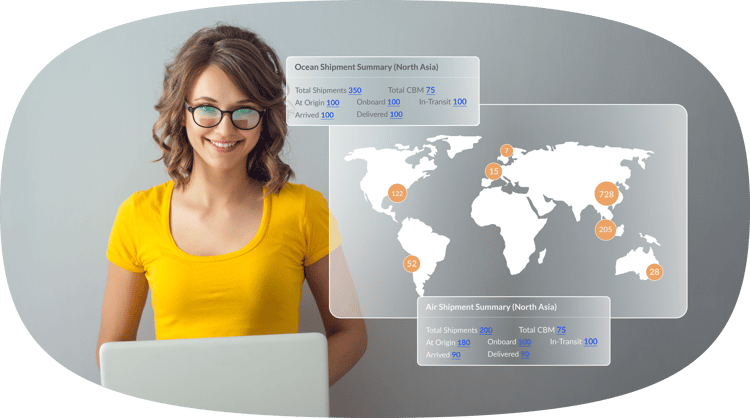

Supply Chain Visibility - End-to-End

Allowing for integration with your ERP, VBO offers visibility and traceability from PO inception down to final delivery, all year round.

From a single platform, you can monitor all your orders and their status, making sure your planning is always up to date, while being alerted of any potential delays on your lead times.

The best part? We train and enable your vendors to use the platform themselves, shifting the workload and accountability of information and allowing for data input without bottlenecks.

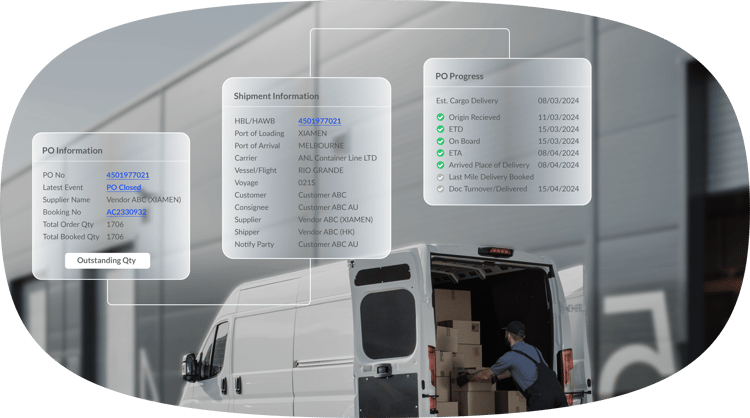

Purchase Order & Milestones Tracking

The Purchase Orders you create in your ERP system are directly available in VBO, with full details. All the Milestones since the PO inception down to final delivery are recorded and available in real time, making it easier to identify if the planning is on time.

Furthermore, VBO allows for status down to SKU level, letting you monitor the items that have more criticality for your orders.

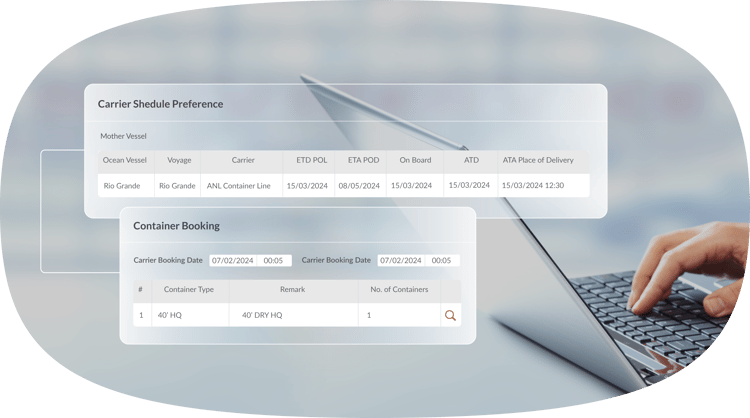

eBooking Portal

Once your Vendors have the PO ready, they can arrange for the bookings themselves, preventing bottlenecks and saving time, all within the convenience of the VBO platform.

Manage all your bookings directly in the platform, ensuring that you know where your cargo is at all times, without losing time in email back and forths or wasting time on the phone. By setting you preferences on container capacity, modal, and criticality on your PO, you can monitor the bookings are being placed on time.

Got your own contracts? VBO caters for BCO carriage, MQC loading and monitoring and carrier management.

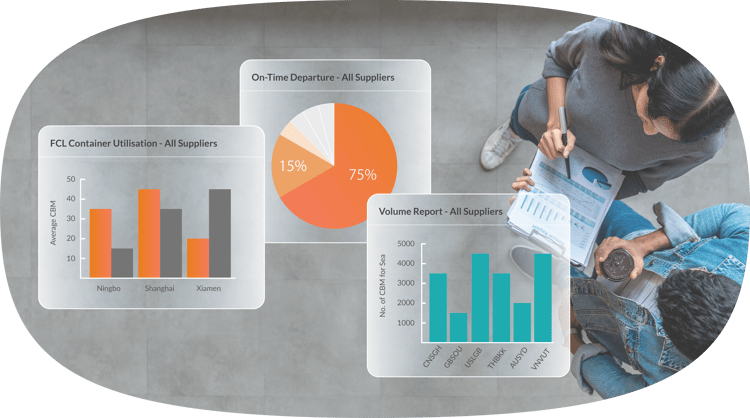

Dashboard Perfomance

The best way to access and understand all your information is to summarize your data with dashboards. Based on your requirements, you can glance upon your key metrics within the Dashboards in VBO, while also receiving detailed reports on a schedule or on demand.

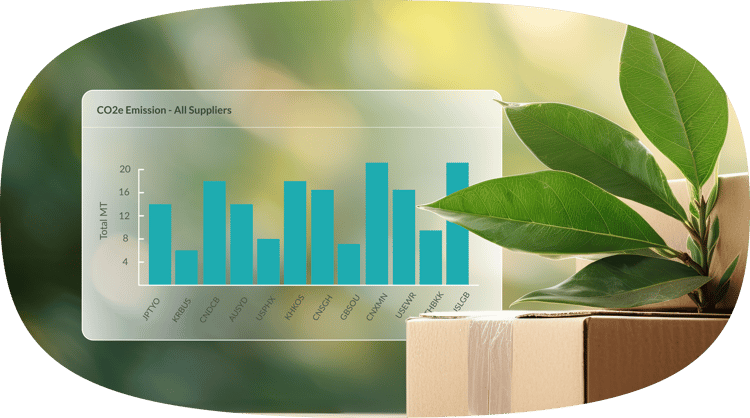

Emissions Dashboard & Reporting

Sustainability is at the forefront of our business and we understand the importance of monitoring your carbon footprint responsibly. Through using VBO, you can have access to carbon emissions reports, with a variety of filter options to sort, organize and download your data.

Other Features

- Vendor automatic follow up. Ensure the tasks are being completed within the timeline assigned and be alerted of any discrepancies.

- Online Vendor Booking. Your vendors can place the bookings based on your shipment preferences, eliminating bottlenecks and allowing you to monitor lead times effectively.

- Document capture. Paperless environment and repositories to have access to all the relevant documents, organized, categorized and accessible at all times.

- Online destination delivery booking.

- EDI/API message exchange.

- SOP bound - complements parameters and requirements defined.

- Scheduled and customised reports.

- Data and information secured by encryption and stored in private servers, with the highest cyber attack barriers in the market. All your information is accessible only through login and authorized IPs, to be defined during the implementation process.

HOW IT WORKS

Zero Defect Implementation

To ensure a successful start-up, we follow a proven project management methodology when introducing new businesses to the Kerry Logistics Network. Full stakeholder engagement and pre-assigned onboarding teams are critical for achieving a zero-defect launch.

This is managed by:

- Applying a methodical stepped approach where business implementation is based on a well-established and proven project management methodology.

- A dedicated on-boarding team will be assigned to the implementation, along with an overall owner of the programme.

- Frequent implementation meetings with all parties concerned attending, meeting minutes, planning, problem-solving, reporting on issues, and overall project timelines.

Exception Management

As part of our process, we define together the parameters of what is acceptable or not in our SOP. Based on this, we program VBO to automatically flag and report any inconsistencies and exceptions in real time, to make sure you get the heads up you need to make any important decisions, joined by our team supporting you every step of the way.

SEAMLESS INTEGRATION

In an ever-evolving and interconnected world, the ability to seamlessly blend various components, systems, and processes is not just advantageous – it's imperative.

Integration between your system and any platform is key to minimizing workload and eliminating data errors due to transfer. Having an integrated supply chain visibility platform allows you to gather the data you need in a single place without fear of data loss and inaccurate feedback.

At Kerry Logistics, we live and breathe integration – making it easier for you to have access to what you need and with the expertise to back up a seamless experience promise.

We start by hosting an EDI workshop to map touch points between systems and determine whether you will get added value from using VBO.

If positive, we

- Prepare an implementation plan (fastest lead time in the market)

- Run UAT error checking before Production is scheduled

- Provide hyper care support after Go-Live

- Continuous monitoring and system connectivity maintenance afterward

As a standard, the touch points we feed back are

- Shipment/Container/Purchase Order level information (E.g. Container number, Quantities etc.)

- Event milestone data (ATD, ATA, Customs Cleared, Delivered etc.)

- Landed Costing information

Our Solution Engineering Team in Adelaide specializes in local data integration and will tailor EDIs (Electronic Data Interchange) or APIs (Application Programming Interface) to seamlessly integrate and enhance connectivity with your existing systems. Our EDI platform supports various file formats (CSV, XML, JSON, etc) through various EDI transport protocols (such as SFTP, API, Email, etc).

To streamline communication, we look at two-way connectivity where possible.

Current Integrations with over 20 ERPS

We are proud to collaborate with some of the most renowned global brands, who are currently leveraging our Virtual Buying Office (VBO) platform.

CUSTOMISED REPORTING AND ANALYTICS

VBO reports can be customised to your requirements, to make sure you make the most out of your data when decision making time comes. This adaptability and flexibility are what enable us to provide state-of-the-art solutions consistently.

As part of our standard reporting, we have available:

- DIFOT

- Invoicing and clearance timelines

- Freight Spend

- Container and Contract Utilization

- Duty Spend

- Volume breakdown

- Pre-clearance times

- Carrier Performance

- Incident Reports

- Trade Lane Data

Furthermore, you are able to choose the frequency and channel to receive your reports.

CASE STUDY - A BCO CUSTOMER USING VBO

Our customer implemented VBO successfully to improve lead times in their supply chain.

Their pain points:

- Updates on cargo received only until arrival was imminent

- Delays in production due to reactive management

- Backlog of materials and operational congestion, causing detention costs

Want to know if this could be a solution for you?